We have hundreds of attendees signed up for our 69th Annual Pump School. If you were thinking of attending, official registration closes tonight, September 8, 2015.

With basic and advance classes, Pump School helps you understand centrifugal pumps, and hone skills.

Session 1 will cover basic hydraulics and include system design, pump selection as well as construction materials, installation and troubleshooting.

Session 2 will cover advanced topics including NPSHA/R calculations, metallurgy, energy efficiency calculations, system curves for pumps in parallel and in series, motors, mechanical seals, and life cycle costs.

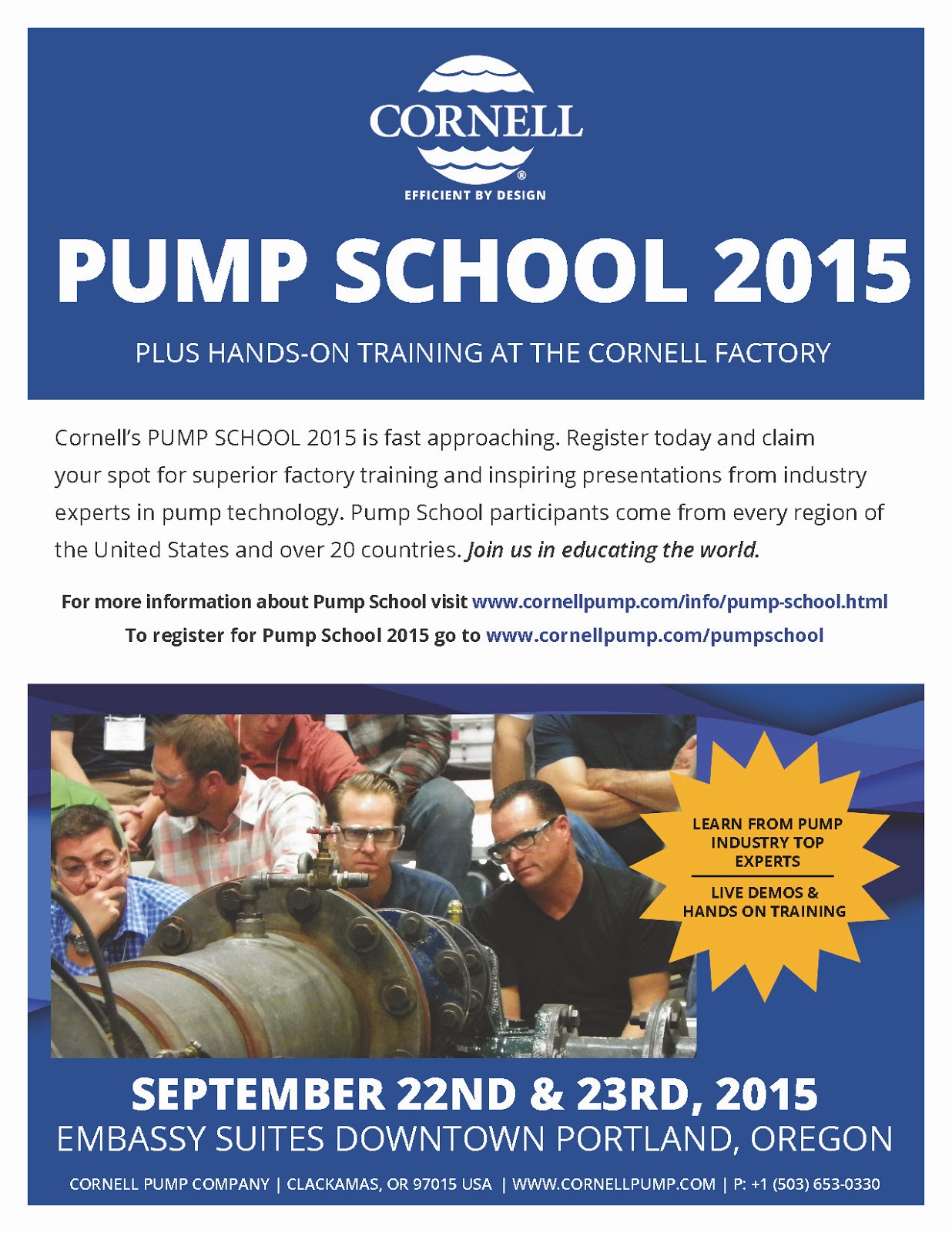

Day two will involve hands-on training at the Cornell factory in the morning, with additional training or seminars in the afternoon.

Breakfast and lunch are provided both days, plus an opening reception before classes start on Monday night, and a hosted dinner on Tuesday night.

Download the Pump School brochure for more information about Cornell's Pump School AND REGISTER TODAY!

Please note: The Cornell Pump block of rooms at the Embassy Suites has been filled as of August 21, 2015. There are still rooms available, however the Cornell Pump School rate does not apply.